Last Updated: December 08 2025

Overview

Stock allocation using Simpro Mobile is based on a specific logic to ensure accountability when items are used on a job. Accurate stock management in Simpro Premium ensures correct material quantities are assigned and a relevant paper trail is created, when stock is used on a job in Simpro Mobile.

It is important to distinguish between the physical process that reflects the actual movement of stock from your storage locations, through your technician's vehicles, to the site for a job, and the digital accounting of stock that occurs in Simpro Premium. Simpro Premium records this movement of stock digitally to reflect the physical movement.

To streamline the stock allocation process in Simpro Mobile, ensure to assign individual storage devices to technicians working on site. Learn more in How to Create Employees.

When you consider stock allocation in a job workflow, it is important to remember that stock is always assigned to a specific cost centre.

Required setup

Required setup

In order to view content or perform actions referred to in this article you need to have the appropriate permissions enabled in your security group. Go to System![]() > Setup > Security Groups and access your security group to update your permissions. The relevant security group tab and specific permissions for this article can be found here:

> Setup > Security Groups and access your security group to update your permissions. The relevant security group tab and specific permissions for this article can be found here:

In order to view content or perform actions referred to in this article you need to have the appropriate permissions enabled in your security group. Go to System![]() > Setup > Security Groups and access your security group to update your permissions. The relevant security group tab and specific permissions for this article can be found here:

> Setup > Security Groups and access your security group to update your permissions. The relevant security group tab and specific permissions for this article can be found here:

Cost centres with no preassigned stock

Cost centres with no preassigned stock

When a technician marks any material as used in Simpro Mobile, the system first checks if any stock is preassigned to the corresponding cost centre they are working on. If no stock is preassigned, Simpro Premium checks a few details to make sure the stock is assigned from the correct storage device.

First, Simpro Premium verifies the technician’s assigned storage device to identify if the stock used is available.

- If the stock is available, the stock is assigned from the technician’s storage device to the cost centre and marked as used.

- If there is insufficient stock in the technician’s storage device, Simpro Premium checks the system default storage device to confirm if the additional stock is available.

- If available, enough stock is transferred from the system default storage device to the technician’s storage device so that the quantity in the technician's storage device is same as the used quantity. The stock is then assigned from the technician’s storage device to the cost centre and marked as used.

- Additionally, if there is no enough stock in either the technician's storage device or the default storage device no additional stock is added to the cost centre, even if it is available in other storage devices.

- If the technician has no storage device set up on their employee card in Simpro Premium, the used stock is assigned directly from the default storage device to the cost centre.

The following examples illustrate this process flow:

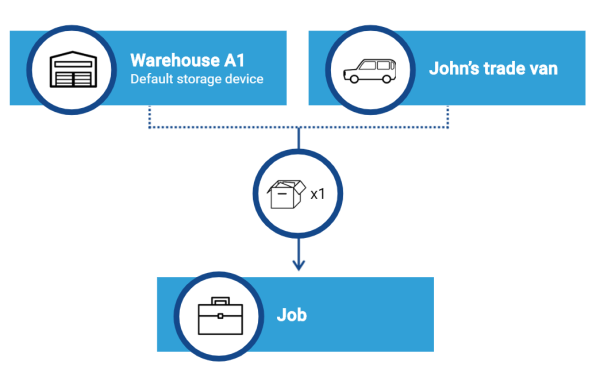

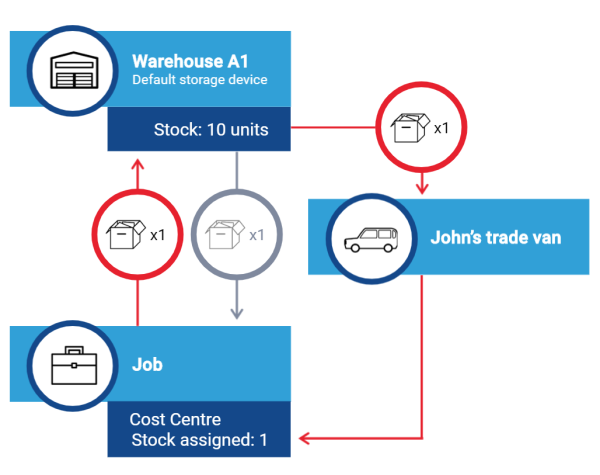

Scenario 1

- A job is created in Simpro Premium with no stock assigned to it.

- The technician on site needs to use a part to complete the job and uses it from his own storage device. And, marks the corresponding part as used in Simpro Mobile.

- Simpro Premium then records that one part is assigned from the stock to the technician's storage device on the cost centre and is marked to be used.

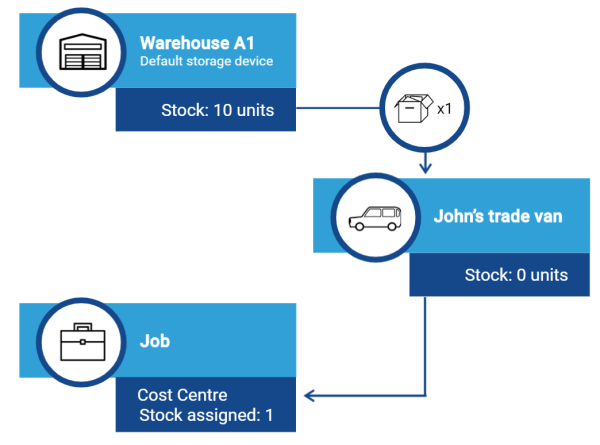

Scenario 2

- A job is created in Simpro Premium with no stock assigned to it.

- The technician on site borrows a part required for the job from the default storage device and marks it as used.

- Since the technician did not perform a stock transfer and just reassigned the parts, Simpro Premium will create a stock transfer for system default storage device to the technician's own storage device and then assign it to the job. This helps create a paper trail that helps identify which technician has used the stock.

Cost Centres with preassigned stock from technician's storage device

Cost Centres with preassigned stock from technician's storage device

When a technician marks a part as used in Simpro Mobile, Simpro Premium first verifies if any stock is preassigned. And, if stock is assigned from the technician's own storage device, this stock is marked as used.

Following possibilities are applicable:

- If there is insufficient stock in the technician’s storage device, Simpro Premium checks the system default storage device to confirm if the additional stock is available.

- If available, enough stock is transferred from the system default storage device to the technician’s storage device so that the quantity in the technician's storage device is same as the used quantity. The stock is then assigned from the technician’s storage device to the cost centre and marked as used.

- Additionally, if there is no enough stock in either the technician's storage device or the default storage device, no additional stock is added to the cost centre, even if it is available in other storage devices.

The following examples illustrate this process flow:

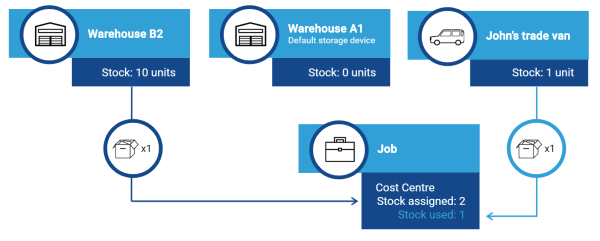

Scenario 3

- A Simpro Premium user in the office is aware that a certain part is required to complete the job and the part is available in the technician's own storage device. Subsequently, they assign the part to the cost centre in Simpro Premium from the technician's storage device.

- The technician on site needs to use two parts to complete the job. He uses one from his own storage device and borrows the other from the default storage device.

- On completion of the work, the technician marks the two parts as used in Simpro Mobile. Simpro Premium then records that one of the parts used was available in the technician's own storage device and other part was sourced from the system default storage device.

- Simpro Premium thereby creates a record of stock transfer for one part, from the system default storage device to the technician's storage device. Next, it assigns the part on to the cost centre and marks both parts as used.

Cost Centres with preassigned stock from system default storage device

Cost Centres with preassigned stock from system default storage device

When a technician marks a part as used in Simpro Mobile, Simpro Premium first verifies if any stock is preassigned. And, if stock is assigned from the system default storage device, the stock is reassigned as follows:

- First, the stock is sent from the cost centre back to the system default storage device.

- Next, the stock is transferred from the system default storage device to the technician’s storage device.

- And then, the stock is reassigned from the technician’s storage device to the job.

Rerouting stock from the default storage device through the technician's own storage device maintains the corresponding technician's accountability for the stock used.

- If the technician uses less amount of stock than the quantity assigned to the cost centre, only the actual quantity required is reassigned using this process.

- If the technician uses more stock than the amount assigned to the cost centre, the additional stock is sourced from the technician's storage device, assigned to the cost centre and marked as used.

- If the technician uses more stock than the amount assigned to the cost centre and the stock in their own storage device is not enough, the additional stock required is transferred from the system default storage device into their storage device, assigned to the cost centre and marked as used.

- If the technician uses more stock than the amount assigned to the cost centre and the stock quantity in either the technician's storage device or the default storage device is not enough, then no additional stock is added to the cost centre, even if it is available in any other storage devices.

- If the technician has no storage device set up on their employee card in Simpro Premium, the stock remains assigned from the default storage device to the cost centre.

The following examples illustrate this process flow:

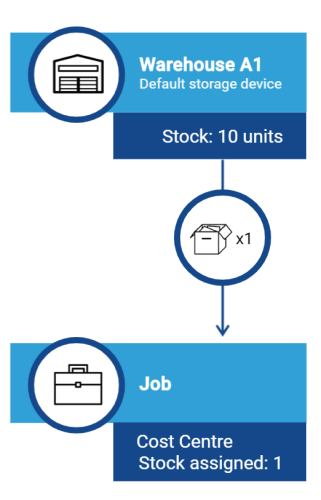

Scenario 4

- A Simpro Premium user in the office is aware that a certain part is required to complete the job and the part is available in the system default storage device. Subsequently, they assign the part to the cost centre in Simpro Premium from the default storage device.

- The technician sources the required part from the system default storage device before travelling on site.

- On completion of the work, the technician marks the part as used in Simpro Mobile.

- To record the transition of the part from the system default storage device to the technician's own storage device to the field, Simpro Premium:

- Unassigns the stock back into the system default storage device

- Transfers the required stock from the system default storage device into the technician's storage device.

- Assigns the stock from the technician’s storage device, on to the cost centre and marks the part as used.

Scenario 5

- A Simpro Premium user in the office assumes that two parts are enough to complete the job and assigns these two parts to the cost centre in Simpro Premium from the system default storage device after checking the stock availability.

- Alternatively, the technician is aware that the job requires only one of the assigned parts. So one of the sourced part from the default storage device is used for the job on site and other part is added to the technician’s storage device.

- On completion of the work, the technician marks the part as used in Simpro Mobile.

- To record the transition of the parts from the system default storage device to the technician's own storage device to using a single part in the field, Simpro Premium:

- Unassigns one of the parts back into the system default storage device.

- Transfers the stock from the system default storage device into the technician's storage device.

- Assigns the stock from the technician’s storage device, on to the cost centre and marks the part as used.

- Leaves the stock that was not used still assigned from the default storage device to the cost centre.

Cost Centres with preassigned stock from a non-default storage device

Cost Centres with preassigned stock from a non-default storage device

When a technician marks a part as used in Simpro Mobile, Simpro Premium first verifies if any stock is preassigned. And, if stock is assigned from a storage device that is not the system default storage device, or the technician's storage device, this stock is not marked as used.

- If the stock is available in the technician’s storage device, the stock is assigned to the cost centre and marked as used.

- If some quantity of stock is used from the technician's storage device and the additional stock required is transferred from the system default storage device into their storage device, it is assigned to the cost centre and marked as used.

- If there is no stock available in the technician's storage device or the system default storage device, no additional stock is assigned.

- If the technician uses more stock than the quantity available in their storage device or the default storage device, the maximum possible amount of stock is transferred to the technician's storage device and assigned to the cost centre leaving the additional stock required not assigned.

- If the technician has no storage device set up on their employee card in Simpro Premium, the stock remains assigned from the default storage device to the cost centre.

Assigning stock to jobs from a non-default storage devices can cause duplications in your stock count and lead to miscalculations in your profit and loss. If you assign stock to a cost centre from a storage device that is not the default storage device, or the technician's storage device, but the stock is available in one of those devices, the stock is assigned to the job the next time when they mark the stock as used.

The following examples illustrate this process flow:

Scenario 6

- A Simpro Premium user in the office assumes that the stock required for a job not available either in system default storage device or the technician's storage device. Therefore, stock is assigned to the cost centre from an another storage device.

- However, the on-site technician discovers that the required part is available in their own storage device.

- On completion of the work, the technician marks the part as used in Simpro Mobile.

- To record the transition of this used part, Simpro Premium assigns the stock from the technician’s storage device to the cost centre and marks the stock as used. Also, the stock that was pre-assigned in the system from another storage device remains assigned to the job and is not marked as used.

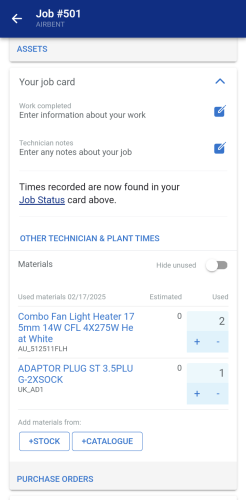

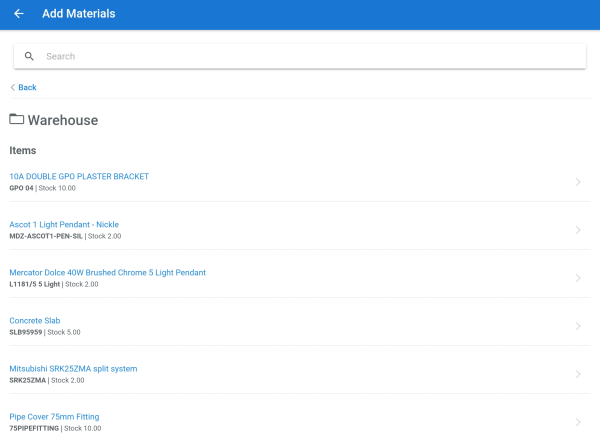

Adding items from stock in the Service module

Adding items from stock in the Service module

When a technician adds a material to a cost centre in the Service module, using the +STOCK option, Simpro Premium considers the following factors for stock assignment:

- If the stock is added from the technician’s storage device, the stock is assigned to the cost centre.

- If the stock is added from a storage device which is not the system default storage device or the technician’s storage device, it is still assigned to the cost centre.

- If the stock is added from the system default storage device, the item is assigned back in the system storage device, transferred to the technician’s storage device, and then reassigned to the cost centre.

When an item is added to a cost centre from stock in the Service module, the item is marked as used by default.

Restricting Storage Device Access in your Simpro Mobile security groups restricts the storage devices that are visible when a mobile user taps +STOCK in the Service module. It does not limit stock from being re-assigned based on how stock is pre-assigned in Simpro Premium.

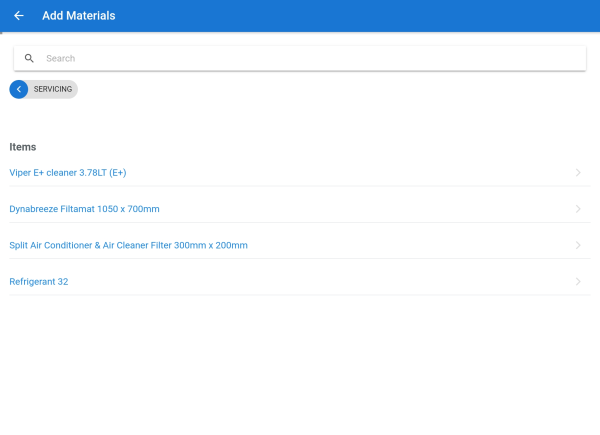

Adding items from the catalogue in the Service module

Adding items from the catalogue in the Service module

If a technician adds material to a cost centre in the Service module, using the +CATALOGUE option and the item is in stock either in the technician’s storage device or the system default storage device, the item is also assigned to the job.

If the item is located in the system default storage device, Simpro Premium creates a stock transfer that moves the item to the technician's storage device before it is assigned and marked as used.

When an item is added to a cost centre from stock in the Service module, the item is marked as used by default.

Learn more in the Learning Toolbox

Learn more in the Learning Toolbox

For additional training, complete an interactive material in the Simpro's Learning Toolbox. Learn more in About Simpro's Learning Toolbox.